A quick guide to different window and door frame types

“What’s the difference between commercial grade aluminium and residential?”

“How does commercial framing differ from other window and door types?”

“What is the most suitable type of frame for my home?”

These are some of the commonly asked questions our team are asked every day, and we are more than happy to help explain how our frame system might set us apart from our competition.

Sometimes knowing what the differences are between all the options available can be a confusing or daunting process, and unless you work in the building industry it might be hard to see and understand the pros and cons.

That’s why we’ve summed up each of the most common frame types for you! From what we do (commercial grade aluminium) right through to uPVC and Timber – it’s important to know your options and what might suit your project best.

Residential Aluminium

Aluminium is a popular choice for Australian homes as it is lightweight, strong and requires little to no maintenance. There are three main grades of framing when looking at aluminium windows and doors, ‘residential/domestic’, ‘semi-commercial’, and ‘commercial’.

Residential/Domestic frames are very common as they are typically made to set standard sizes and designs, so you can generally get these in a faster timeframe and at a lower cost. Some common window dimensions include 600x1400mm, 1200x1800mm, 1800x1400mm, 2100x2100mm.

The framing has a smaller profile and lightweight appearance; however, the glass may be thinner (even if double glazed), you may experience draughts, and the frame may eventually require replacement if not fabricated and installed correctly.

Due to the slim size of the framing, it does not tend to perform as well from an energy efficient perspective, additionally, the frames have weight/size limitations which means that the glass panels have to be split (and so will have more design divisions).

Semi-Commercial Aluminium

Semi-Commercial is the middle-child of the aluminium family. The framing is more customisable, slightly bigger, stronger and more stylish than that of residential frames, but smaller and more cost effective than commercial frames. In turn, the glass can be thicker and larger in size than standard residential options, however you can’t achieve the same size or energy performance which commercial framing can.

Commercial Aluminium

Commercial framing is the top the range option, designed with commercial applications in mind, this frame type can go big in size, is stronger, more durable and comes with longer-lasting hardware. Typically used for architecturally designed homes or high-rise buildings, it’s now becoming more common in everyday residential homes too.

If you want to achieve full height windows or doors from floor to ceiling, then commercial framing will likely be the best choice – this range is designed to withstand higher wind-loads and more intense weather events.

Commercial framing has a larger glazing channel, this means it can accommodate much thicker glass to allow for extra-large feature windows – think BIG! Like 9-12 square meters of glass in a single window! You can read more about glass thickness requirements here.

Another example of the sizes this frame type can achieve is with sliding doors. For example, residential sliding doors might only be 2400mm in height, semi-commercial might be 2700mm in height, but with commercial framing, we can go to 3100mm – or taller!

At Nuline Windows, we choose to only use commercial grade framing for its strength, durability, and so we can fabricate custom designs and sizes.

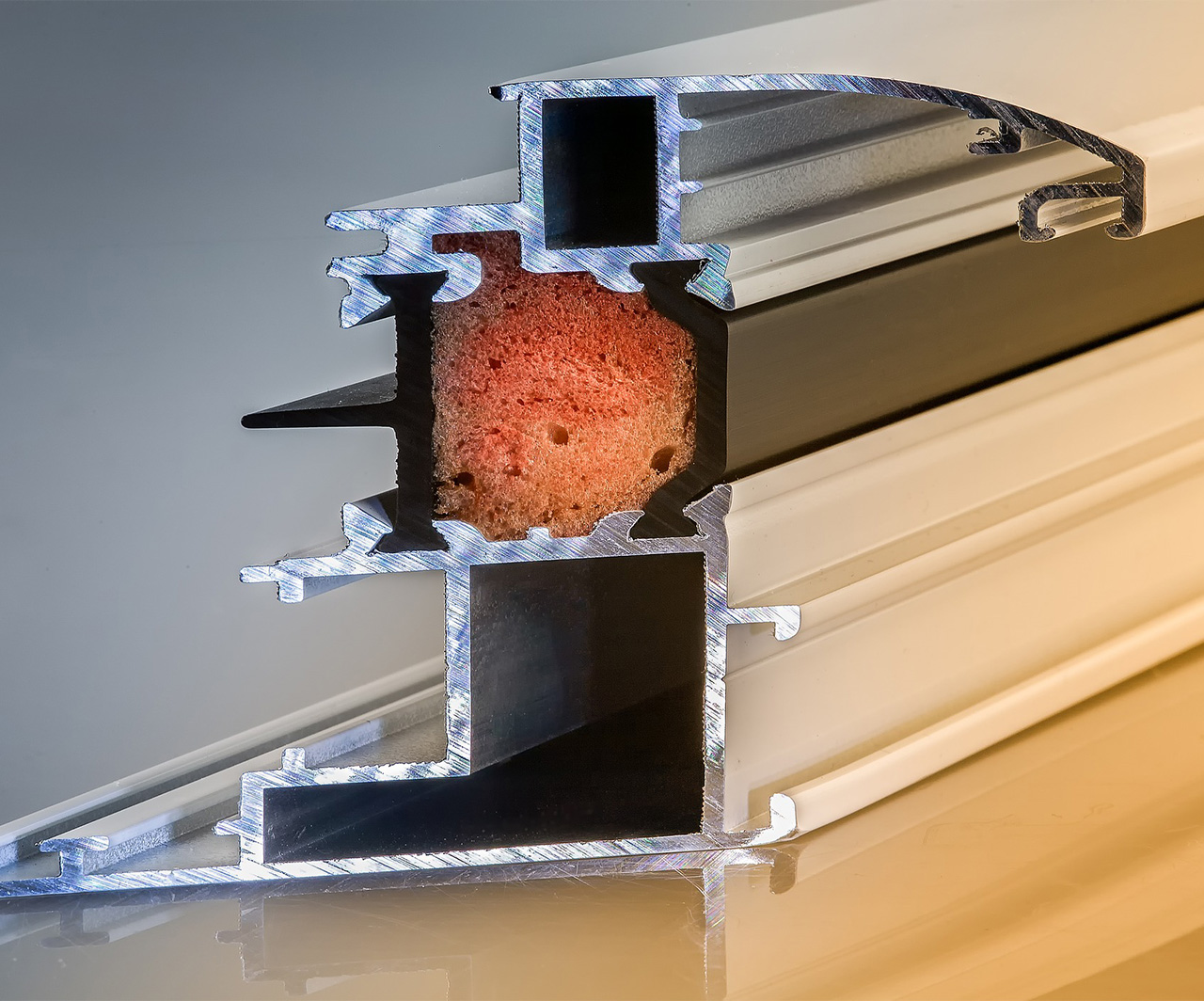

Thermally Broken Aluminium

Thermally broken aluminium framing is the premium choice when it comes to aluminium framing and energy efficiency. It has the same overall appearance as standard commercial aluminium but features a reinforced polyamide strip which separates the outside and inside sections of frame. This strip creates an insulated barrier to slowdown and minimise the transfer of conducted heat/cold.

Combined with a high performance LowE glass type, thermally broken frames can provide ultimate performance values for both U-Values (conducted heat) and SHGC values (solar heat).

Depending on the window and door type, thermally broken framing can have a slightly ‘chunkier’ appearance than commercial frames and if you have a very large window or door, then standard commercial framing may be a better choice for overall strength as it is one whole length of aluminium and is not split by the thermal strip.

The main downside of thermally broken framing is its price tag, this type of framing can increase the cost by as much as 40-60% (depending on how much framing your project has).

Timber

Timber windows will always be a popular option for their aesthetic and traditional appearance; additionally, if you ever decide to re-decorate, you can change the colour of the frames quite easily.

As with all things natural, they can change with the weather, this means seasonal shrinking and swelling which may compromise your ability to open and close windows and doors. Good quality hardwood is best, but you might find that it will come at a cost to your project.

Timber is popular from an energy efficiency and acoustic standpoint; it also has a high weight to strength ratio for large window and door panels.

When not maintained correctly, over time you may find that issues arise from draughts, rot, mould or termites. Rot can be particularly nasty as if not treated early and properly, it can cause expensive damage to other areas of your home around the windows and doors.

Steel

Steel frames are another traditional and classic frame material, historically used for industrial settings, they are very popular for ‘maximum glass’ appearances and fire-rated applications. Steel frames offer long lasting solutions with almost minimal maintenance.

One of the most popular features of steel frames are their slim and classic appearance, because of the strength of steel, the framing sections can be much smaller than that of any other frame material.

One of the downsides of steel is the initial cost of the frames, and so they are often used for impressive entrances and feature rooms only, while the rest of the home has a different frame type.

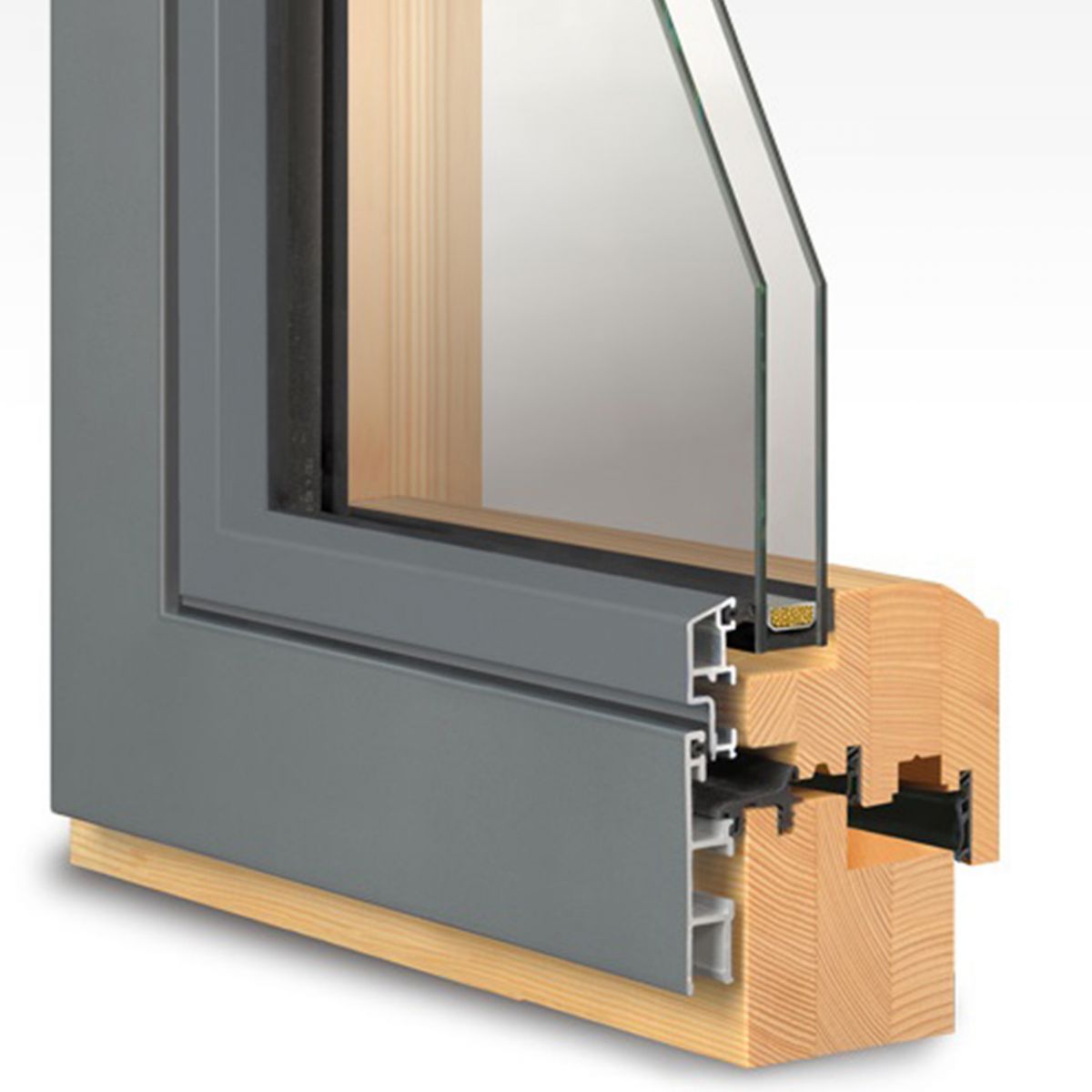

Composite

Composite windows are fabricated using two or more materials, typically they are a combination of uPVC, aluminium and/or timber. One of the most common combinations is aluminium clad on the outside for durability and timber on the inside for insulation and appearance.

Composite windows perform quite well for energy efficiency but are also more on the expensive side of window and door options. Similar to residential or semi-commercial aluminium, another compromise for this style of framing is that it also has design and size restrictions.

uPVC

uPVC (Un-plasticised Polyvinyl Chloride) windows are becoming more popular in Australian markets as they are one of the most cost-effective options available. Performing in a similar way to timber and composite frames, uPVC can work well for your home’s energy efficiency.

Unfortunately, uPVC does come with its downsides, they typically have a shorter lifespan compared to other materials and they can warp and discolour over time. Originally from American and European markets, this material was not designed with the harsh and varied Australian environment in mind.

Unlike steel or commercial aluminium, and like composite or residential aluminium, uPVC also has design and size limitations for how big your windows and doors can be – this might mean unnecessary divisions and having to compromise on style and size to fit with set sizes and designs.