Anodising Aluminium

These days there’s a wide variety of colour and finish options available for aluminium windows and doors. But how do they do it and what does it mean? Colour customisation of aluminium is done mainly by two different processes, either powdercoating or anodising. In this blog, we will talk about anodising in detail.

What is anodising?

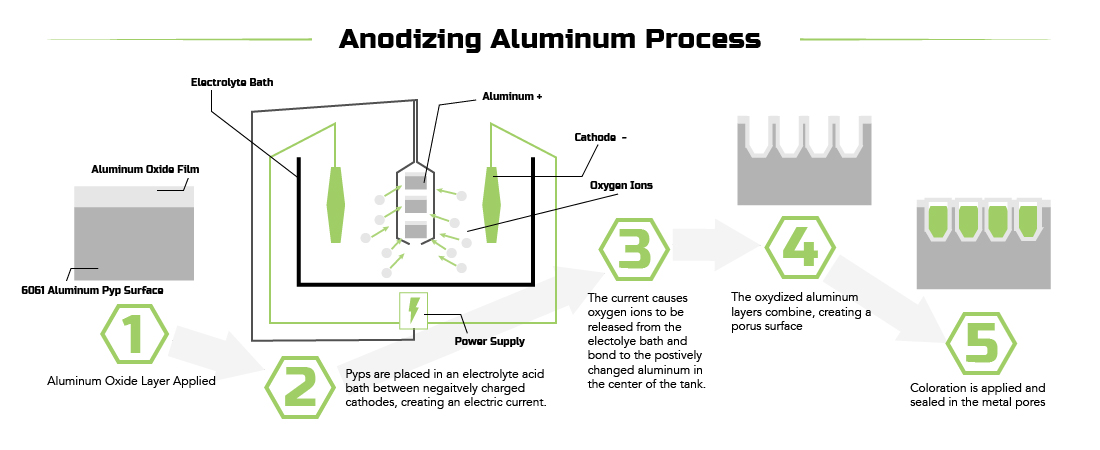

Anodising aluminium involves an electrochemical process in which a decorative or a protective layer is fully integrated into the metal surface, making it less susceptible to scratches, abrasions and most types of corrosion.

In simple words, anodising adds a hard layer on top of the metal.

How is it done?

After being thoroughly cleaned, the metal is immersed into an acid eletrolyte bath, and an electric current is passed through. A cathode is mounted in the tank, and during the process, pores are created on the aluminium surface when then erode down into the metal to varying depths. The aluminium on the surface combines with the Oxygen ions released by the acid to create aluminium oxide, also known as a 'barrier layer'.

The porus surface to the metal can have colour applied in varying tints and pigments.

Available colour options

There are over 25 different shades to choose from when anodizing aluminium, and we have several companies we can source from. Please note that colour selection can affect the lead time of your project, some options are stocked by our suppliers and some have to be specially ordered. Some colours are also more costly than others, our friendly team would be happy to order any samples you might like, and price them up for your project as required.

Get in touch with Nuline Windows to discuss your anodised aluminium needs and we will be happy to help and discuss your project requirements.

Example 'coloured' anodised aluminium extrusions

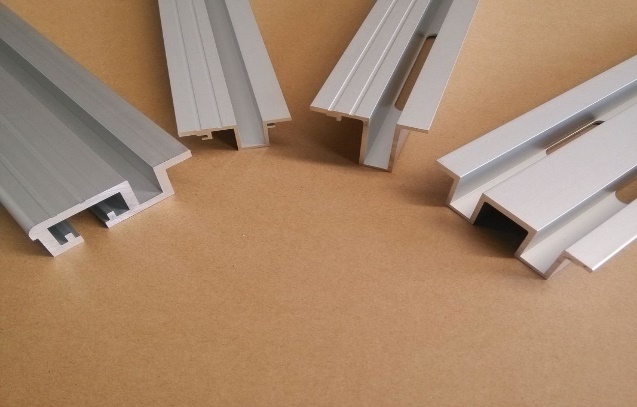

Example 'natural' anodised aluminium extrusions