Glass thickness requirements – AS1288

At Nuline windows and doors, we only manufacture our frames with commercial grade aluminium framing, this frame profile allows us to build our products to almost any size we want and accommodate designs with huge spans of glass.

In order to adhere to Australian Standards, the glass which we choose for your windows or doors will depend on its location in your home/build, its height, width and area size. That is why we always ask for as much information as possible so we can quote accordingly for your project’s needs.

AS1288 (2006) is the Australian Standard which determines the specific glass type and thickness requirements for all buildings across the country. Adherence to AS1288 (2006) means that we often need to use thicker glass for our larger windows and doors than what some may expect.

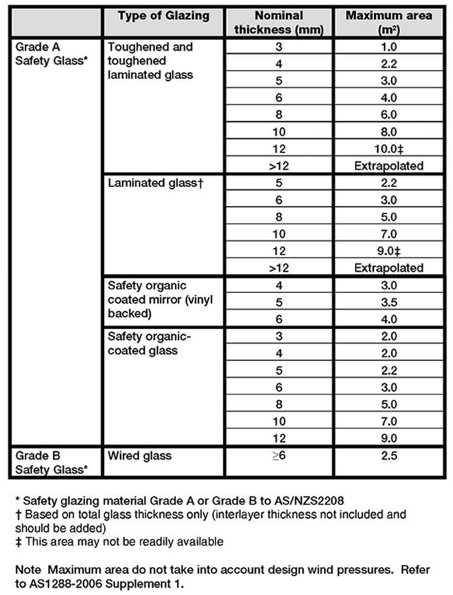

We only ever use two types of safety glass in our projects, laminated and toughened as they pose minimal risk of injury when broken. Ordinary ‘float’ glass can be very dangerous as if it breaks, it can form large and sharp shards.

Glass ranges in thickness depending on its physical makeup, toughened glass can be typically supplied between the thicknesses of 3 - 12mm and laminated glass can typically be between 5 - 12mm.

At Nuline we almost always do not supply single glazed glass in our projects thinner than 6mm (toughened or laminated); and 4mm/16/4mm in double glazed units. This is to ensure strong glass and high quality finished projects.We are constantly referring to the below tables which dictate maximum areas for safety glass (for fully framed windows and doors):

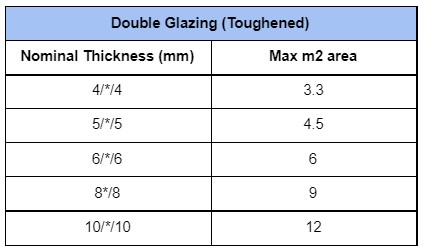

Maximum Area of Safety Double Glazed Toughened Glass:

Note though that when it comes to toughened glass, we often opt to go one step above the code to ensure that glass roller wave is kept to a minimum.

Maximum Area of Safety Single Glazed Glass (extracted from AS1288-2006 Table 5.1):